Makina opangira zitoliro zamalata osinthika

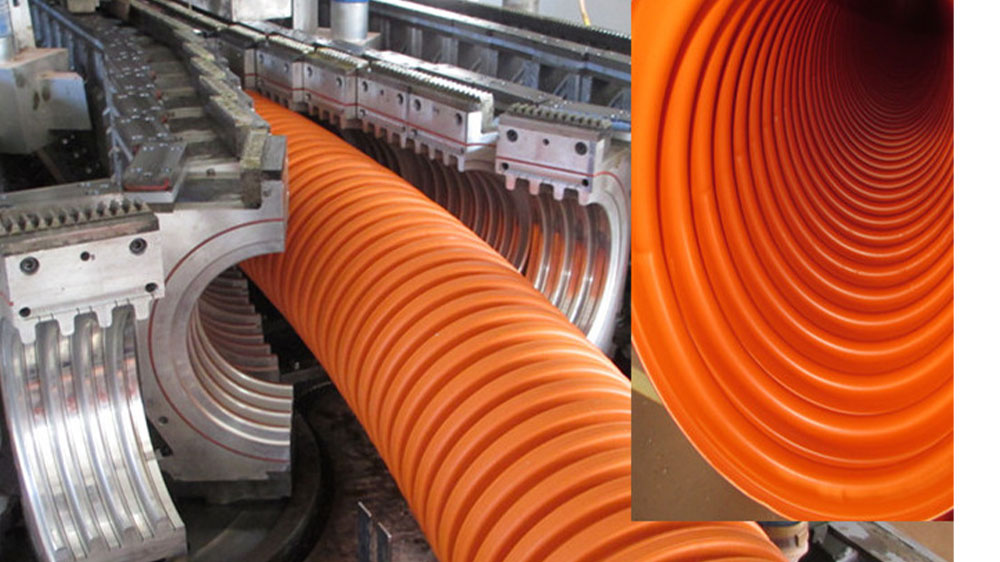

pulasitiki limodzi khoma malata chitoliro extrusion mzere angabweretse PP/Pe/PVC/EVA/PA malata chitoliro.Mould unyolo utenga zida kufala, mbale m'munsi utenga madzi kuzirala, nkhungu utenga mpweya kuzirala.

Chitoliro cha malata opangidwa ndi makina athu ali ndi mbali ya liwiro mkulu kupanga, ngakhale malata mawonekedwe, molunjika chitoliro msoko, ndi pamwamba yosalala.Ndi okonzeka ndi vacuum mpope ndi zingalowe mtundu nkhungu, akhoza kupanga ntchito zosiyanasiyana malata chitoliro ndi olowa (kusamba beseni kuda chitoliro, chitoliro air conditioner, chitoliro cha hookah etc.)

Mzere Extrusion kupanga single-khoma ndi awiri khoma malata machubu ndi mapaipi opangidwa Pe, PP, PVC, PA, Eva, PVDF, TPE etc.

Main Technical Parameter---Single Wall Corrugated Pipe Make Machine:

| Extruder Model | SJ45 | SJ65 |

| M'mimba mwake (mm) | 45 | 65 |

| Chiwerengero cha L/D | 28-33:1 | 28-33:1 |

| Chitoliro m'mimba mwake | 9-32 | 32-110 |

| Ma module awiri | 42 (50) | 50 |

| Liwiro la mzere (m/mphindi) | 3-15 | 3-15 |

| Module njira yozizira | Woziziritsidwa ndi mpweya | Woziziritsidwa ndi mpweya |

| Chitoliro kuzirala njira | Woziziritsidwa ndi mpweya | Woziziritsidwa ndi mpweya |

| Ufa wonse woyika (kw) | 50 | 70 |

Ntchito zazikulu:

Makampani omanga: ngalande yamagetsi & payipi yaukhondo / chitoliro chosinthika cha siphon, PP-PE-PVC-PA

Makampani opanga magalimoto: Chitoliro chamafuta & ma chubu a waya, PP-PA6-PA11-PA12-PA612

Makampani azachipatala: machubu opumira, LLDPE,EVA

Mitunduyi imaphatikizapo: Choyala choziziritsa madzi, choyala chopangira chowotcha, choyala chopangira makina ovundikira, choyala cholumikizira motsatizana, cholangira cha kutalika kwa unyolo wosiyanasiyana.

I: mawonekedwe a pulasitiki corrugation chitoliro kupanga makina

1. PP/PE/PA/PVC/EVA mzere kupanga angagwiritsidwe ntchito kupanga mipope-khoma malata umodzi.

2. Mapaipi apulasitiki okhala ndi khoma limodzi ali ndi mawonekedwe a kutentha kwambiri, kugonjetsedwa ndi dzimbiri ndi abrasion, kulimba kwambiri, kusinthasintha kwabwino, ndi zina zotero. mipope zoteteza nyali ndi nyali waya, machubu a air conditioner ndi makina ochapira, etc.

3.Plastic single-khoma corrugated chitoliro kupanga mzere kupanga ndi kampani yathu utenga zida kuthamanga zisamere pachakudya ndi zidindo kuti kuzindikira madzi kuzungulira kuzirala ndi mpweya kuzirala wa mankhwala, amene amaonetsetsa mkulu-liwiro akamaumba, ngakhale corrugation, yosalala mkati ndi kunja chitoliro. khoma.Mapaipi a malatawa amagwiritsidwa ntchito makamaka ngati mawaya a magalimoto omwe akugulitsidwa kwambiri.

II: ndondomeko ya pulasitiki corrugation chitoliro kupanga makina

chopakira → Sing'anga chopondera → Ifa → Kupanga nkhungu → Thanki yamadzi (posankha) → Chotsani ndi chodulira (posankha) → Wowomba kawiri wogwirira ntchito

III: Zida zamakina opangira chitoliro cha pulasitiki

PVC PP PA PE EVA

IV: kugwiritsa ntchito chitoliro chamalata

waya wamagetsi, mapaipi odutsa ulusi wamagetsi, kuzungulira kwa chida cha makina

mipope zoteteza nyali ndi nyali waya, machubu a air conditioner ndi makina ochapira, etc.

luso chizindikiro cha pulasitiki corrugation chitoliro kupanga makina

Ndi chitsulo chapadera cha aluminium alloy mold bolck chokhala ndi mankhwala odana ndi kumatira, mpweya wozizirira, madzi ozizira ndi vacuum channel mkati mwa chipika cha nkhungu zimatsimikizira kupanga bwino kwa chitoliro ndi liwiro.

Kapangidwe wapadera kufa kupanga makulidwe a mkati ndi kunja khoma ngakhale, ndi khola akamaumba.Kuonjezera apo, makulidwe a mkati ndi kunja akhoza kusintha.

Ndi gawo lapadera komanso lolondola lopanga; Kuzirala kwa mpweya ndi madzi kumatsimikizira kuthamanga kwachangu.

| Chitoliro m'mimba mwake | 4.5mm-12mm | 9mm-32mm | 12-63 mm | 32mm-110mm | 50mm-160mm |

| Chitsanzo cha extruder | SJ45 | SJ50 | SJ65 | SJ75 | SJ90 |

| Mphamvu zopanga | 20-30 kg / h | 40-50kg / h | 60-70kg / h | 70-90kg / h | 100-120KG/H |

| Mphamvu ya extruder | 7.5kw | 15kw pa | 30kw pa | 37kw pa | 55KW |

| Mphamvu yopanga makina | 1.1kw | 1.5kw | 4kw pa | 4kw pa | 4KW pa |

| Ma module awiri | 42awiri | 50awiri | 50awiri | 72awiri | 72awiri |

| Kuziziritsa mode | Kuziziritsa kwa Mphepo & Madzi | Kuziziritsa kwa Mphepo & Madzi | Kuziziritsa kwa Mphepo & Madzi | Kuziziritsa kwa Mphepo & Madzi | Kuziziritsa kwa Mphepo & Madzi |

| Liwiro la kupanga | 6-10m/mphindi | 8-12m/mphindi | 8-12m/mphindi | 2-6m/mphindi | 2-6m/mphindi |

| Main makina chitsanzo | SJ-45 | SJ-65 | SJ-65 |

| Kutalika kwa chitoliro (mm) | 4.5-9 | 9-32 | 16-50 |

| Makina akulu L/D | 30:1 | 28:1 | 33:1 |

| Mphamvu yopangira (kg/h) | 30 | 60 | 100 |

| Mphamvu yayikulu yamagalimoto (kw) | 4 | 15 | 22 |

| Mphamvu yamakina (kw) | 1.1 | 1.5 | 2.2 |

| Ma module awiri | 38 | 72 | 90 |

| Liwiro la kupanga (m/mphindi) | 6-10m.min | 25m/mphindi | 30m/mphindi |

| Kuziziritsa mode | Kuziziritsa kwa mphepo ndi madzi | ||

| Njira yoyezera | Inducting mode | ||

| Makina a coiling mode | Zoyendetsedwa ndi injini, zoyendetsedwa pamanja | ||

SJ-65 PE PP Khoma Lokhalokha Paipi Yowonjezera Chitoliro

| Mkhalidwe wautumiki | 380-/3Phase/50HZ |

| Zofunika : | PVC/PP/PE |

| Mtundu wa mapaipi: | 16-23 mm |

Single-Screw Extruder ya SJ—65/30:

| Speed frequency regulator | |

| Sikirini | 1). M'mimba mwake : 65mm2).Utali ndi m'mimba mwake chiŵerengero cha wononga : 30:13). Zopangira wononga: 38CrMoALA, pansi pa mankhwala a nayitrogeni4).Kuzama kwa wosanjikiza wa nayitrogeni wa wononga: 0.4-0.6mm,kuuma: HV> 740 |

| Mgolo | 1) . The zinthu mbiya: 38CrMoALA, pansi nayitrogeni mankhwala .Kuzama nayitrogeni wosanjikiza wa mbiya: 0.5-0.7mm, kuuma: HV> 9403) mbiya Kutentha : 4 Kutentha gawo ,Zinthu za Kutentha bwalo: chitsulo chosapanga dzimbiriKutentha mphamvu : 6kw * 4 zigawo4) . Kuzirala kwa mipiringidzo: 4 kuzirala gawo, Kuzirala mphamvu: 0.18kw * 4sections ( fan blower) |

| Galimoto | Kuyendetsa galimoto mphamvu: 22kw |

| Mphamvu ya extruder | 80kg/h |

| Makina odzaza zinthu zamagalimoto | |

| Kuchepetsa gearbox | 1) .Speed reducer ndi ya dzino lolimba pamwamba2) . Zida za zida ndi 20CrMoTi pansi pa nayitrogeni, kuzimitsa ndi kupukuta mankhwala.3) Zokhala ndi chipangizo chozizira chakunja.Chidachi chimakhala ndi mphamvu zonyamula katundu, kufalitsa kosasunthika, phokoso lochepa komanso luso lapamwamba, ndi zina. |

| Ifa mutu | ||

| 1 | Zida zamutu | 40Cr |

| 2 | Mapangidwe amkati | Mtundu wa Spiral |

| 3 | Sungunulani pressure mita | Khalani ndi mita yothamanga kuti muyang'ane kuthamanga kwa kusungunuka mu mutu wa kufa |

| Makina opanga & kupanga nkhungu 16 ndi 23mm makulidwe awiri.  | ||

| 1 | Zinthu zopangira nkhungu | 40Cr, mankhwala a nayitrogeni |

| 2 | Kupanga nkhungu | 1 seti |

| 3 | Kuchuluka kwa chipika cha nkhungu | 90 pawiri |

| 4 | Kupanga makina amtundu | Mtundu wopingasa |

| 5 | Kupanga nkhungu kusuntha njira | Kuzungulira |

| 6 | Yendetsani mphamvu yamagalimoto | 3 kw |

| 7 | Inverter | DELTA |

| 8 | Njira yozizira | Kuziziritsa mpweya |

| 9 | Mphamvu ya blower | 85w × 5 seti |