PVC chitoliro kupanga mzere (50-200mm)

| Mzere wopanga mapaipi a PVC1 seti Double-Screw Extruder - SJSZ65/132 Ndi injini ya INOVINCE SERVO, yapamwamba kwambiri 1 set auto screw loader 1 seti Nkhungu kwa 50.63.75.90.110MM 1 yakhazikitsa Nkhungu ya 125.140.160.200MM Seti imodzi ya Vacuum calibration yozizira tanki 1 makina atatu onyamula mbozi 1 makina odulira mapulaneti 1 seti ya Stacker |

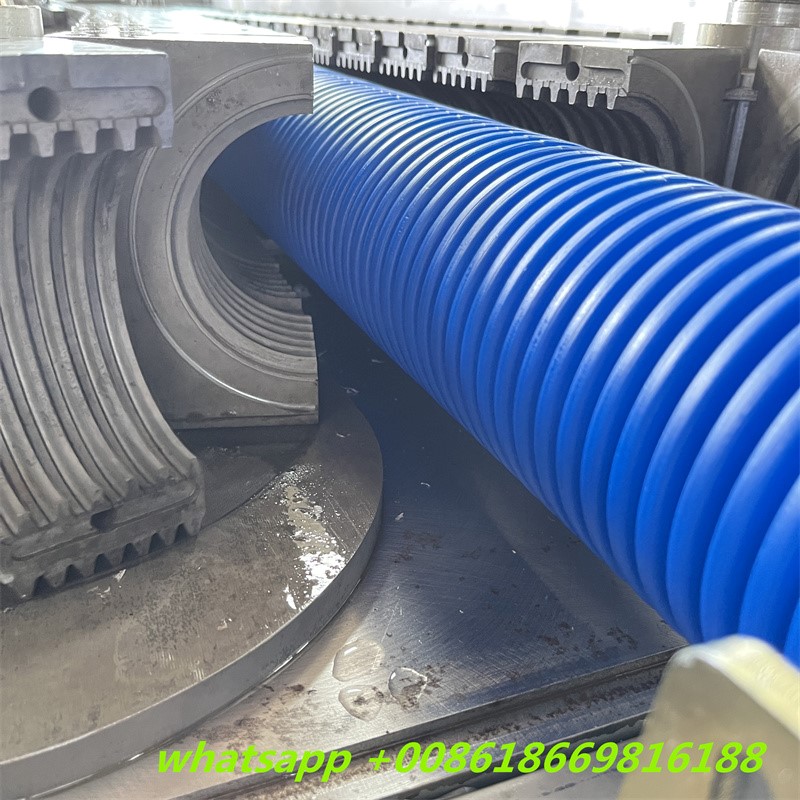

| SHR300/600 chosakaniza chotentha komanso chozizira |

| Makina ojambulira chitoliro a PVC okhala ndi nkhungu yamtundu wa U |

| SWP500 crusher yokhala ndi ntchito yochapaku crusher PVC chitoliro kuchokera 20-250mm 22kw galimoto Kusuntha mpeni 7 ma PC, kukonza mpeni 2 ma PC, linanena bungwe 400-500kg/h |

| Makina osindikizira a PVC |

| ﹡Screw, kapangidwe ka mbiya ndi kupanga zimatengera ukadaulo wapamwamba waku Europe ﹡Zingwe ndi mbiya zakuthupi: 38CrMoAlA, chithandizo cha nitriding ﹡adopt zida zamagetsi zodziwika bwino zokhala ndi mawonekedwe othamanga kwambiri.Mwachitsanzo: RKC kapena Omron chowongolera kutentha, chowongolera liwiro la AC, chowotcha chochepa mphamvu chimatengera Schneider kapena Nokia ﹡Gearbox imatengera torque yayikulu, phokoso lotsika, bokosi la giya lolimba la mano ﹡Kudziteteza: chitetezo chamakono cha motor overload automatic stop screw displacement automatic stop chitetezo Chida chodzidzimutsa chamafuta ndi njala Chophimba ndi mbiya | |||

| 1 | Screw Diameter | mm | 65/132 |

| 2 | Kutalika kwa screw | mm | 1430 |

| 3 | Zinthu za Screw ndi Barrel | / | 38CrMoAlA Chithandizo cha Nayitrojeni |

| 4 | Kuzama kwa kesi ya nitration | mm | 0.4-0.7 mm |

| 5 | Kuuma kwa nitration | HV | 940HV |

| 6 | Kukala kwa pamwamba | Ra | 0.4 gawo |

| 7 | Kuuma kwa ma aloyi awiri | Mtengo wa HRC | 55-62 |

| 8 | Kuzama kwa ma aloyi awiri | mm | 》2 |

| 9 | Kutentha Mphamvu | KW | 24 |

| 10 | Kutentha kwa Barrel | / | Kuponyera Aluminium Heater |

| 11 | Kuzirala kwa Mimbi | / | Kuzirala kwa chowuzira phokoso chochepa |

| Mlandu wopatsira | |||

| 1 | Mulingo woyenera | / | JB/T9050.1-1999 |

| 2 | Zida za gear ndi shaft | / | Atengere mkulu mphamvu aloyi, carburizing ndi kuzimitsa, akupera |

| 3 | Kulondola kwa zida ndi kuuma | / | 6grade, HRC 54-62 |

| 4 | Kusindikiza mafuta | Kusindikiza kulikonse kumatengera zinthu zabwino | |

| 5 | Screw Safeguard | / | Alamu yoyimitsa yokha |

| Dosing kudyetsa chipangizo | |||

| 1 | Mtundu | / | Screw dosing feeder |

| 2 | Kudyetsa mphamvu zamagalimoto | KW | 1.5 |

| 3 | Kudyetsa liwiro wowongolera | / | INOVINCE Brand inverter |

| Motor ndi magetsi dongosolo | |||

| 1 | Mphamvu Yamagetsi | KW | 37(INVOVINCE SERVO MOTOR) |

| 2 | Kuwongolera liwiro | / | Holip kapena kusintha kwina kodziwika kwa Frequency conversion |

| 3 | Kuthekera Kwambiri Kutulutsa | Kg/h | 50-300 kg |

| 4 | Vacuum exhaust system | / | pampu ya vacuum |

| 5 | Temperature Controller | / | Siemens/DELTA/OMRON |

| 6 | AC cholumikizira | / | Siemens/DELTA/OMRON |

| 7 | Voteji | / | Malinga ndi zofunika |

| 8 | Kutalika kwa axis extruder | mm | 1000 |

2. Kufa mutu kwa PVC chitoliro kuchokera 50-200mm

| Kanthu | Kufotokozera | Ndemanga |

|

| ||

| 2 | Zinthu za thupi la nkhungu | Chitsulo 45 # (wapamwamba nkhungu chitsulo) |

| 3 | Zinthu zamkati mwa nkhungu | 40Cr (wapamwamba nkhungu chitsulo) |

| 4 | Zinthu za calibrator | Mkuwa |

| 5 | Makulidwe a khoma la chitoliro (Pressure rate) | Monga kufunikira |

3. VACCUM PUMP CALIBRATION TANK yozizira

Vacuum Calibration ndi Tanki yozizira

| Kanthu | Kufotokozera | ZK-200 | |

| Ntchito: yeretsani m'mimba mwake ndikuzizira | |||

| 1 | Utali | 6000 mm | |

| 2 | Zinthu za tank | chitsulo chosapanga dzimbiri | |

| 3 | Mtundu Wozizira | Madzi Kutsirira-kutsanulira kuzirala | |

| 4 | Mphamvu ya Pompo ya Madzi | 4KW × 2 ma PC | |

| 5 | Mphamvu ya Pampu ya Vacuum | 5.5KW × 1pcs | |

| 6 | Kusintha malo kumanzere ndi kumanja | Kusintha pamanja | |

| 7 | kuyenda mmbuyo ndi mtsogolo | Yoyendetsedwa ndi mota (mtundu wa cycloidal-pin wheel) | |

4. Gulu lonyamula mbozi zitatu

Zida zitatu zonyamula zida zonyamula makina

| Kanthu | Kufotokozera | QY-200 |

| Ntchito:Jambulani PVC chitoliro patsogolo stably, liwiro ndi synchronized ndi extruder liwiro. | ||

| 1 | Mtengo wa Pedrail | 3 |

| 2 | Pedrail wide | 55 mm |

| 3 | Kutalika kwa Pedrail | 1900 mm |

| 4 | Max.Hauling Force | 20KN |

| 5 | Pedrail Clamping ndi kutulutsa Mode | Pneumatically Drive |

| 6 | Kutulutsa Mphamvu Yamagetsi | 2.2KW |

| 7 | Kuthamanga Kwambiri | 0.5-5m/mphindi |

| 8 | Kuthamangitsidwa ndi kufala | Central drive;kufala kwa cardan |

| 9 | Kuthamanga Kusintha Mode | Kusintha pafupipafupi kutembenuka |

| 10 | Kutalika kwa Axis | 1000 mm |

5. Planet Cutting Machine

| Kanthu | Kufotokozera | CH-200 | |

| Ntchito:Mamita kuwerengera basi kudula PVC chitoliro mu utali wokhazikika. | |||

| 1 | Kudula mode | Makina owerengera mita | |

| 2 | Kudula mphamvu zamagalimoto | 2.2kw | |

| 3 | Revolution motor Mphamvu | 1.5KW | |

| 4 | Kudula masamba | Kudyetsa kwa hydraulic | |

| 5 | Kusonkhanitsa fumbi | Ndi chowuzira mpweya ndi 1.5kw | |

| 6 | Clamping ndi kumasula Mode | Mwachiwopsezo | |

| 7 | Kubwerera kwautali kusuntha | Ndi mpweya silinda pneumatically | |

| 8 | Zowona | Chitsulo chabwino cha Alloy | |

| 9 | Njira zowongolera | Malingaliro a kampani Siemens PLC | |

| 10 | Mtundu wa inverter | Schneider mtundu | |

6.Stacker

| 1 | Chitsanzo | SFL-200 |

| Kugwiritsa ntchito:Pangani mapaipi a PVC. | ||

| 2 | Zinthu za board board | Chitsulo chosapanga dzimbiri |

| 3 | Utali | 6M |

| 4 | Njira yochotsera | Kutulutsa pneumatic |

| 5 | Kutalika Kwapakati | 1000 mm |

| 6 | Kusintha Utali | ± 50 mm |

| 7 | Kulemera | 480KG |