Granulator

Mkulu wapamwamba linanena bungwe otentha pulasitiki pellet / chitoliro / cubeextruder makina pulasitiki yobwezeretsanso zida

SJ mndandanda single wononga extruder pulasitiki makina makamaka ntchito extrude PP, Pe, PET, PVC, ABS, PS, PA ect material.It amatengera zida bokosi wapadera, ndipo ali mbali ya otsika phokoso, kuthamanga khola, mkulu kunyamula mphamvu, moyo wautali utumiki. .Okonzeka ndi nkhungu zosiyanasiyana ndi zida wothandiza, akhoza kupanga chitoliro pulasitiki, pepala, bolodi, granules ndi zina zotero. Iwo ali mbali ya ndondomeko yosavuta, linanena bungwe mkulu, kuthamanga extrusion khola, ndi mtengo wotsika.

| Ntchito: DJ85 single screw pelletizing line |

| Zopangira & chilinganizo | PE mafilimu |

| Chomaliza | PE granules |

| Mphamvu zotulutsa | 120-200kg / h , zimadalira makhalidwe a zinthu. |

| Kutalika kwapakati | 1.14m |

pp pelletizing mzere pulasitiki wobwezeretsanso granulating makina zinyalala pulasitiki granules kupanga makina

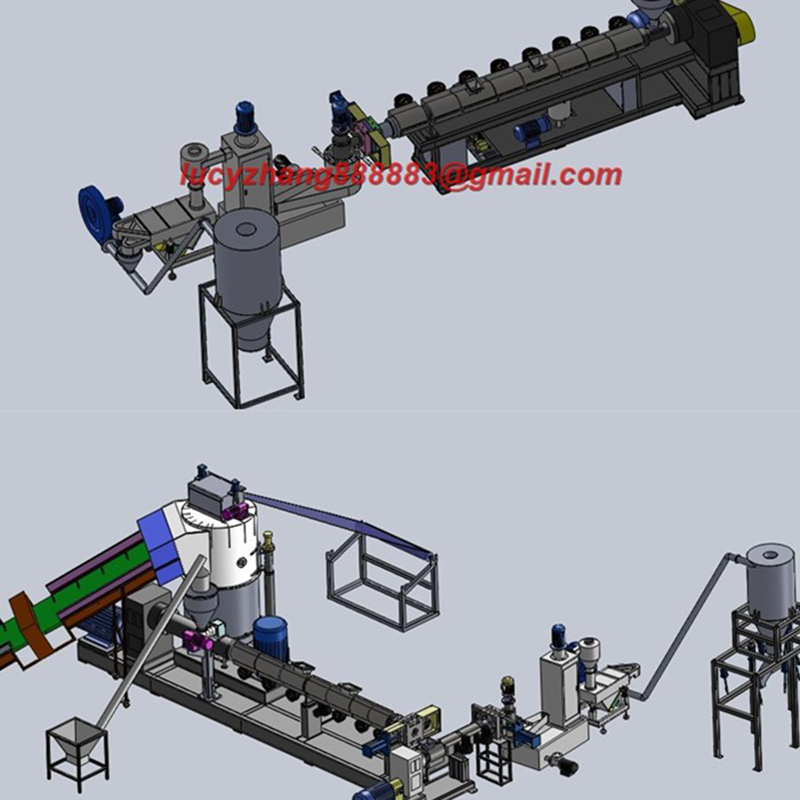

Zoyendera(CS Series Double Stage Compactor-Granulator):

| Model(double stage) | CS85-100 | CS100-120 | Chithunzi cha CS130-150 | Chithunzi cha CS160-180 | CS180-200 |

| M'kati mwake (mm) | 85 | 100 | 130 | 160 | 180 |

| L/D | 25-42 | 25-42 | 25-33 | 25-33 | 25-33 |

| Kuthekera (kg/h) | 150-200 | 300-350 | 500 | 600-700 | 800-1000 |

Ntchito:

PE, PP film, Silika, Flakes (≤0.5mm), Matumba, etc.

Zindikirani, makina athu a CS compactor granulator amatha kukhala njira yodulira mizere, kapena njira yodulira mphete yamadzi kuti musankhe

Muli:

Wonyamula lamba(chojambulira zitsulo) → Kompakita → Chotulutsira mpweya chachikulu(zotsekera mpweya) → Chosinthira chophimba cha Hydraulic → Sub- extruder →

Chosinthira chophimba cha Hydraulic → Makina odulira mphete zamadzi → Makina otsitsa madzi → Makina owombera mpweya → Chosungira chosungira → kabati yowongolera

1. Zina zambiri

1.1Malo apansi

Zomangamanga zoyambira, zapansi, ntchito zapakhoma ziyenera kumalizidwa bwino ndi Wogula povomera chingwe cholumikizira ichi.

Wogula ayenera kupereka crane, forklift kapena zida zina zonyamulira, zida zoyikapo ndi zida.

Dera: kuti ipangidwe molingana ndi masanjidwe a mzere.

1.2Magetsi

Mphamvu zoyikidwa:106KW (kugwiritsa ntchito mphamvu moyenera kudzakhala pafupifupi 70%)

Magetsi:

Mphamvu zamagetsi: 3 * 380V + N + PE;

Kulekerera kwamagetsi: + 10%/-5%;

Mphamvu yamagetsi: 24VDC + 220VAC;

pafupipafupi: 50Hz+-2%

Waya/zingwe:

- Mawaya / zingwe kuchokera kumagetsi kupita ku kabati yowongolera (zoperekedwa ndi Wogula).

- Zingwe zonse zamagetsi kuchokera ku kabati yowongolera kupita ku makina aliwonse (operekedwa ndi Wogula).

1.3Madzi

Kagwiritsidwe:0.6T/h (madzi obwezeretsanso)

Madzi ozizira:

Popanda kusungunuka kapena kuyimitsidwa mchere monga phosphor, sulfure, chitsulo, etc.

Kutentha kolowera T1: max.15 ℃

Kutentha kwa kutuluka T2: T2=T1+5℃

Kuthamanga kolowera, min: 2.5 mipiringidzo

Kuuma: 5-8ºdH;

Reflux: popanda kukakamiza

Madzi payipi:

Kuchokera pamadzi kupita ku makina aliwonse (operekedwa ndi Wogula).

1.4Mpweya woponderezedwa:0.6M3/ min, 0.4 ~ 0.7Mpa

1.5Ogwira ntchito

2-3 Anthu

1.6Mafuta odzola

Kupezedwa pamsika wakomweko pamawu a Seller (operekedwa ndi Wogula).

2. Zolinga zamalonda

2.1Machine list & Price

| Ayi. | Dzina la Chipangizo | Chitsanzo | Zambiri (zokhazikitsidwa) |

| 1 | Wonyamula lamba | | 1 |

| 2 | Kompakita | | 1 |

| 3 | DJ85/33 single screw extruder | DJ85/33 | 1 |

| 4 | Plate Type Hydraulic screen chosinthira160 | | 1 |

| 5 | Madzi mphete kudula dongosolo | | 1 |

| 6 | Makina ochotsa madzi pawindo la vibrating | | 1 |

| 7 | Silo | | 1 |

| 8 | Kabati yamagetsi | | 1 |

2.2 Malipiro

- 40% monga gawo la T / T.

- 60% ngati muyezo ndi T / T musanaperekedwe komanso mutayang'anira.

2.3 Nthawi yotumiza

M'masiku 50 ogwira ntchito kuyambira tsiku lolandira gawo.

2.4 Kupakira

Filimu yapulasitiki.

2.5 chitsimikizo

Miyezi 13 ya zida zamakina kuyambira tsiku lonyamula katundu.Chitsimikizo cha miyezi itatu pazinthu zamagetsi ngati magetsi mufakitole ya Buyer sakhazikika.

cuishi amalipira mtengo wa Wogula pazigawo zotsalira zida zitatha chitsimikiziro ndikupereka chiwongolero chaukadaulo chanthawi yayitali.

2.6 Kukhazikitsa & Kutumiza

- Wogula ayenera kukonzekera kuyika zida zikafika, monga magetsi, madzi, zogwirira ntchito ndi ma cranes, ndi zina.

- Cuishi adzakonzekera kufunsira visa kwa mainjiniya, omwe amapita ku fakitale ya Wogula kuti akatumize ntchito.

- Wogula akuyenera kulipira matikiti a ndege obwereranso kwa mainjiniya ngati chitupa cha visa chikavomerezedwa, ndi ndalama zoperekedwa monga ma visa, chakudya, malo ogona ndi chilolezo cha USD100 patsiku kwa injiniya aliyense.

2.7 Kutsimikizika

- Masiku 60 kuchokera tsiku lomaliza.

3. Mafotokozedwe aukadaulo

3.1DJ85 Single screw extruder

| 1 | Wonyamula lamba |

| | Monga mapangidwe okhazikika, zinyalala za pulasitiki monga filimu, silika, zingwe, matumba, nsalu zosalukidwa zimatumizidwa mu bin yophatikizira ya cuishi kudzera mu chipangizo chodyera lamba.Kuthamanga kwa chipangizo chodyera lamba kumalumikizidwa ndi kudzaza kwa bin yophatikizira, ndipo liwiro lotumizira zinthu zonyansa limangosinthidwa malinga ndi kudzaza kwa bin.Motor mphamvu: 1.5kw M'lifupi lamba conveyer: 400mm Kutalika kwa mayendedwe: 5000mm Ndi chowunikira zitsulo: Mtundu waku China |

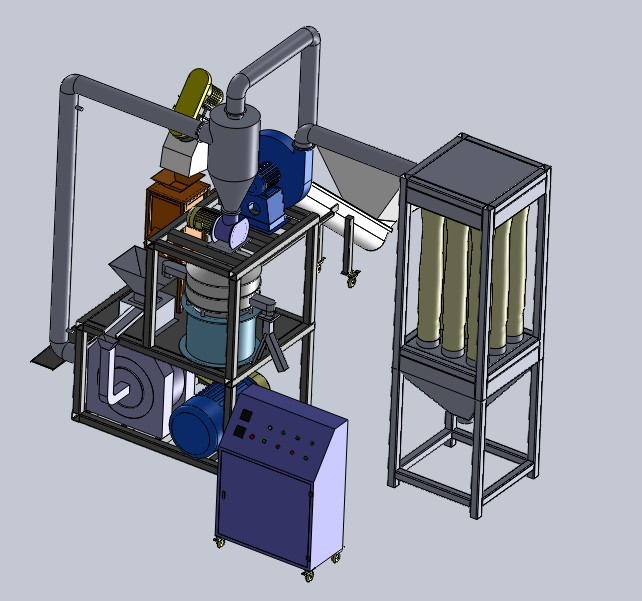

| 2 | Kompakita |

| | Mpeni wosunthika mu bin yophatikizira umazungulira kudula ndi kuphwanya zinyalala zomwe zimalowa mu nkhokwe.Mpeni woyendayenda wothamanga kwambiri, pamene ukuphwanya zinthuzo, umatulutsa kutentha kozizira kuti ziwumitse zinyalala zisanachitike.Panthawi imodzimodziyo, mothandizidwa ndi njira yoyendetsera kutentha yomwe imapangidwira mwapadera ndi kayendedwe ka liwiro, zinyalala zowononga kutentha zimakonzedwa kale pansi pa kutentha kwa kutentha.kuchepa.Zinyalala zomwe zisanachitike zimaphwanyidwa ndi polowera mkati mwakhoma la silo, ndikukakamizika kulowa mumgolo wa extruder ndi mphamvu ya centrifugal ya mpeni wozungulira.Kupyolera mu ndondomekoyi yophatikizika yophwanyidwa, kuyanika ndi kuphatikizika, kukhazikika ndi kuyendetsa bwino kwa kudyetsa zinyalala ndi kutsika kochepa kwambiri kumatsimikiziridwa. Mphamvu yamagetsi: 37kw Kuwongolera kutentha Njira yozizira: kuziziritsa madzi Kuchuluka kwa masamba ozungulira: 4PCS Makulidwe a masamba okhazikika: 9PCS Chizindikiro: NSK Zigawo zomwe zimagwirizanitsidwa ndi zinthu ndi zitsulo zosapanga dzimbiri |

| 3 | DJ85/33 Single screw extruder |

| | Gawo lapadera la ndondomeko (mbiya, wononga) lopangidwira mitundu yosiyanasiyana ya zowonongeka zimatha kusungunula ndikupangitsa kuti zinyalala zomwe zidapangidwa kale zipangidwe mokoma. Zinyalala za pulasitiki zidzasungunuka kwathunthu ndi kupangidwa ndi pulasitiki mkati mwa ndondomeko yomwe mukufuna kutalika kwa 32D mpaka 36D. Gearbox: torque yayikulu, phokoso lotsika, mano olimba akugaya bokosi lamagetsi lozungulira kunja Njinga mphamvu: 55kw, pafupipafupi kulamulira ndi inverter Kuthamanga kwa screw: 0 ~ 120rpm Zida za screw ndi mbiya: 38CrMoA1A, chithandizo cha nitride Mkati pamwamba mankhwala makulidwe: 0.4 ~ 0.7mm, L/D: 33:1 Diameter ya screw: φ85mm Njira yozizirira: kakamizani njira yozizirira mphepo Njira yowotchera: ndi ma heaters Zone yotenthetsera 6 Kutentha mphamvu pafupifupi 48KW Njira yozizira Kuzizira fani: 0.33KW X 5 = 1.65KW Dongosolo la Double Vacuum Degassing: Pampu yamagetsi: 2.2kw Kalembedwe kasefera: kusefera kwamadzi. Chipinda cha vacuum: kapangidwe kapadera, magawo awiri. Vacuum chubu: kutentha ndi kupanikizika kupirira machubu a rabara. Kutulutsa koyenera kwa zinthu zosasunthika monga ma micro-molecule ndi chinyezi chochokera kusungunuka kuti ma granules akhale abwino. Zodzitetezera: Kutetezedwa mochulukira kwa injini. Kutetezedwa kopitilira muyeso kwa screw. |

| 4 | Plate Type Hydraulic screen chosinthira160 |

| |  | Makulidwe (mm) | | d1 | d2 | d3 | d4 | h1 | h2 | D1 | D2 | D3 | N-M1 | N-M2 | L | W | H | | Φ280 | Φ254 pa | Φ254 pa | Φ280 | 6 | 6 | pa Φ380 | Φ330 | Φ266 | 12-M24 | 8-M20 | 420 | 230 | 480 | | Malo osefa | Mphamvu | Kutentha mphamvu | Mphamvu ya Hydraulic | Kupanikizika | Kutentha | | 550cm² | ≤2200kg/h | 10.2kw | 3 kw | ≤35MPa | ≤350 ℃ | |

| Single-plate double-station screen changer: · Chotenthetsera chooneka ngati mphete chotenthetsera chosasintha komanso chokhazikika. · Kuthamanga kopanda kutayikira ndikusintha mwachangu pazenera. · Chida chosindikizira chosinthika. · Chophimba chosapanga dzimbiri: cholondola kwambiri, chosavala komanso chosasunthika. Kutalika: 160 mm Njinga mphamvu hayidiroliki: 2.2kw |

| 5 | Madzi mphete kudula dongosolo |

| |     |

| | 1. Liwiro la tsamba la pelletizing limangosinthidwa mpaka ma pellets omaliza a yunifolomu awonekere.2.Chipangizo cha pneumatic chimagwiritsidwa ntchito kudyetsa mpeni kuti zitsimikizire kulumikizana kwabwino pakati pa tsamba ndi kufa, ndipo kukakamiza kwa mpeni kumasinthidwa kukhala kuonetsetsa yunifolomu kudula mphamvu ya mpeni. Yambitsani dongosolo ndi kiyi imodzi kuti ntchito ya dongosolo lonse ikhale yowonjezereka yabwino; Chodula nkhope chopingasa Mphamvu ya wodula: 2.2kw Mphamvu mpope madzi: 2.2kw Wodulayo amawongolera pafupipafupi ndi inverter |

| 6 | Makina ochotsa madzi pawindo la vibrating |

| Chiwonetsero chapamwamba cha dewatering vibrating chophatikizidwa ndi kuyanika kopingasa kwa centrifugal kumatha kukwaniritsa kuyanika bwino komanso kugwiritsa ntchito mphamvu zochepa.cuishi imatenga mawonekedwe otsekedwa ndipo imakhala ndi chivundikiro chosamveka bwino, chomwe chimakhala ndi phokoso lochepa komanso chosavuta kugwiritsa ntchito. Njinga mphamvu: 0.25kw*2. Magawo omwe amalumikizana ndi madzi: SUS304. Sonkhanitsani sieves: osati welded.Kukhazikitsidwa ndikukhazikika ndi zomangira, kuti zitheke kusintha masieve atsopano mtsogolo. Akasupe azunguliridwa ndi mphira, kuti apewe kusiyana kwakukulu kwa matalikidwe chifukwa cha kukalamba kwa masika. Mapangidwe apadera oletsa zonyansa zazing'ono kugwera mu mpope wamadzi. Mphamvu yamagetsi: 3kw. Kuthamanga kwa rotary: 1460 rpm Magawo omwe amalumikizana ndi madzi ndi ma granules: SUS304. |

| 7 | Silo |

| | Mphamvu yogwira: 700LMaterial ya gawo pokhudzana ndi zinthu zosapanga dzimbiri |

| 8 | Kabati yamagetsi |

| | Dongosolo lowongolera limagwiritsa ntchito kuwongolera kwa Nokia, ndipo lili ndi mawonekedwe ogwiritsira ntchito amagawo a mafakitale (chinthu chosankha) - Smart pa: Boot ya kiyi imodzi

Malinga ndi kutsatizana koyenera komanso zofunikira pakuwongolera zinthu, makina olumikizana a cuishi amazindikira kuyambika kwa kiyi imodzi, motero amapewa kulakwitsa poyambira. - Kutseka kwanzeru: kutseka kwa kiyi imodzi

Mothandizidwa ndi chipangizo chopangidwa mwapadera, makina a cuishi amatha kuzindikira kutseka kwa kiyi imodzi ya gawo lonse la dongosolo kuti apewe kuwonongeka kwa zida zomwe zimachitika chifukwa chogwiritsa ntchito molakwika panthawi yotseka pamanja. - Chipangizo choyimitsa mwadzidzidzi

cuishi imakhala ndi ntchito yoyimitsa mwadzidzidzi, yomwe imagwiritsidwa ntchito ngati mwadzidzidzi paziwopsezo zosadziwika panthawi ya makinawo, kutseka dongosolo lonse mwachangu komanso mwachangu kupewa ngozi zachiwiri ndi kuvulala. Chida choteteza chitetezo cha moyo Dongosolo la cuishi limaganizira mokwanira zachitetezo cha zida panthawi yogwira ntchito.Malo aliwonse ogwiritsira ntchito komanso malo ozungulira ali ndi zida zosinthira zamagetsi kuti zitsimikizire chitetezo cha zida panthawi yogwira ntchito ndikupewa zoopsa zomwe zingachitike panthawi yogwiritsira ntchito zida zomwe zingayambitse vuto kwa ogwiritsa ntchito kasitomala. - Kusungidwa kwa pulasitiki

Mothandizidwa ndi ndondomeko yoyenera yoyendetsera kutentha ndi ndondomeko yokonzekera bwino ya gawo la plasticizing process, dongosolo la cuishi lingathe kutsimikizira kudalirika ndi kukhazikika kwa khalidwe lomaliza la pelleting. - Chipangizo chotetezera kutentha kwa chipinda chophatikizira

Mothandizidwa ndi mfundo yoyendetsera modular komanso kuzindikira kwathunthu magwiridwe antchito azinthu zosiyanasiyana zobwezerezedwanso, makina a cuishi amatha kuwonetsetsa kuti zinyalala zomwe zasinthidwa zimakwaniritsa bwino kutentha ndi kuphatikizika m'chipinda chophatikizika, ndipo zitha kupewa kuti zinthu zobwerera pulasitiki zisamangidwe. .Kutentha kwambiri kapena kuwonongeka kwa nyumba yosungiramo katundu. Wothandizira: Schneider Kutumiza: CHNT Kusintha kwakukulu: CHNT Wosokoneza dera: CHNT Chidziwitso: Makasitomala akuyenera kupereka waya kuchokera ku kabati yowongolera kupita ku makina aliwonse.

|